Bedding is what we call the interface between the stock and the receiver. The action screws clamp the receiver into the bedding area of the stock.

Stress Free Bedding

A good bedding job is a stress free bedding job. But what does that mean, exactly? Why does it matter?

To understand the role of bedding in accuracy, it helps to start with understanding just how easy it is to make the receiver bend. And to also understand just how much clamping force the action screws really have.

Receiver Deflection Force

Let’s start with how easily a receiver can be forced to bend. Using a long action Remington 700 as an example, demonstrations show that hanging 100 pounds from the rear action screw will cause the receiver to deflect as much as .038.

Okay, so a hundred pounds of force perpendicular to the rear of the action will cause it to be deflected a quite noticeable amount. But who puts that much force on the rear action screw? You do! And I do too. In fact, we put way more than 100 pounds of force on them!

Action Screw Clamping Force

It requires only 5 inch/pounds of torque on a ¼ inch action screw to create 100 pounds of clamping force. Do you use only 5 inch/pounds of torque on your action screws? Me neither. So 30 inch/pounds of guard screw torque creates 600 pounds clamping force. The often recommended 65 inch/pounds creates 1300 pounds of clamping force. But it only takes a measly 100 pounds of force to bend the action by .038.

The take away message here, is that we very easily create far more than enough force to cause receivers to bend by simply tightening the action screws in a normal manner.

Receiver Stress From Poor Bedding

So, we have typically two action screws, front and rear. What happens if there is a high spot in the stock inletting, in the bedding area, between the two action screws? We go ahead and tight the action screws and pull the receiver down into the bedding and yup, you guessed it, the receiver will simply bend on that high spot.

This puts stress into the receiver. Even a tiny imperfection in the bedding can result in significant bending stress on the receiver. Think of it somewhat like a spring that has tension applied to it and is just waiting to be let loose. That receiver wants to return to its normal straight self, the tension in it wants to move. That, is stress in the receiver created by poor bedding.

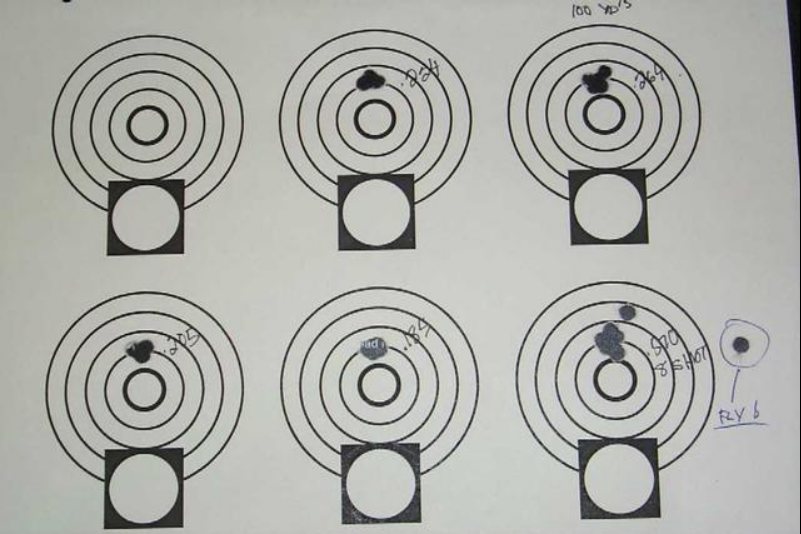

When you fire your rifle, all kinds of violent movement happens. Far too fast for our eyes to see, but it’s there. The approximately 55,000 pounds of pressure released in a fraction of a second causes a great deal of movement, stress and strain. During this brief but violent and somewhat chaotic event, the deflection stress in the receiver is trying to be released. That spring wants to be sprung! If it were released perfectly consistent and able to react and move during firing exactly the same for every shot, we’d never notice it. But, it doesn’t act perfectly consistently and this causes our bullets not to leave the barrel when it’s pointed in precisely the same spot as consistently as possible.

This is how putting stress into the receiver with poor bedding reduces accuracy potential.

How To Check Bedding For Stress

So, stress free bedding is what we want. We want the receiver to maintain its stress free, relaxed state without any deflection when the action screws are tightened. There are a number of ways to complete a stress free bedding job, maybe we’ll get into that some other time. For now though I’m going to show you a super easy way to check the bedding for stress.

The way I like to check bedding, is to start by clamping the muzzle end of the barrel in a vise (wood blocks to protect the finish, of course!). With the rifle firmly held by the barrel, setup a magnetic base dial indicator to read any movement between the barrel and the tip of the stock.

If you don’t have a magnetic mount dial indicator, get one! You can find them at Harbor Freight or online for $20 and they have a million and one uses.

With the rifle held by the barrel and the dial indicator on the tip of the stock, loosen the rear action screw and watch the dial indicator. If there is a high spot in the bedding and any bending in the receiver, the receiver will try to return to its at rest shape by pushing the stock away when you loosen that screw. If the dial moves, you’ve just identified stress in your bedding!

Check both action screws, one at a time, looking for movement of the dial as you loosen and re-tighten them.

You’ll likely see some flickering of the dial, no matter what. But don’t worry about it if it’s just barely wiggling the dial. But if it’s moving a few thousandths, you might want to consider a new bedding job. If you are striving for really top level accuracy and the dial is moving .004 or more, you’ll definitely want to address the bedding. For factory rifles that haven’t had any bedding work at all done to them, seeing movement of .010 or more is common. I’ve seen factory bedding move the needle .050 or more! It’s no wonder that bedding a factory rifle so often makes a noticeable improvement in accuracy!

– DAA

I didn’t know that even a tiny imperfection in the bedding can result in significant bending stress on the receiver. My husband has a rifle and has been wondering how he can make it more accurate. That is good to know that he can get rifle bedding done to help it out.

Bedding almost always improves accuracy. Done correctly, it never hurts!