My .17 Predator

by Dave Affleck

The impetus for building my .17 Predator came when I read Dan Clements first article about building his in Small Caliber News. I’ve been talking to Dan on various internet sites for years, and have a great deal of respect for his knowledge and passion. I knew he had been working on a new large capacity .17 caliber wildcat, but not until I read his article about designing the cartridge and building a rifle for it, did the details really hit home for me. The results he was getting — a 30 gr. bullet, with a B.C. of .270, at 4100 fps, really fired up my imagination. Those numbers put the big .17 in a whole new class over the old .17 Remington. I already knew that the 25 and 30 grain .17 caliber bullets at high velocity are excellent coyote thumpers that kept fur damage to a minimum. But I had visions of a rifle that could serve double duty. A coyote calling rifle that would deliver extremely flat trajectory and sufficient downrange energy to anchor coyotes, while still allowing me to spot my own shots without needing a muzzle break, all in a rifle light weight enough to be carried all day. That sure sounded like one heck of a good setup for stalking rock chucks above timberline too!

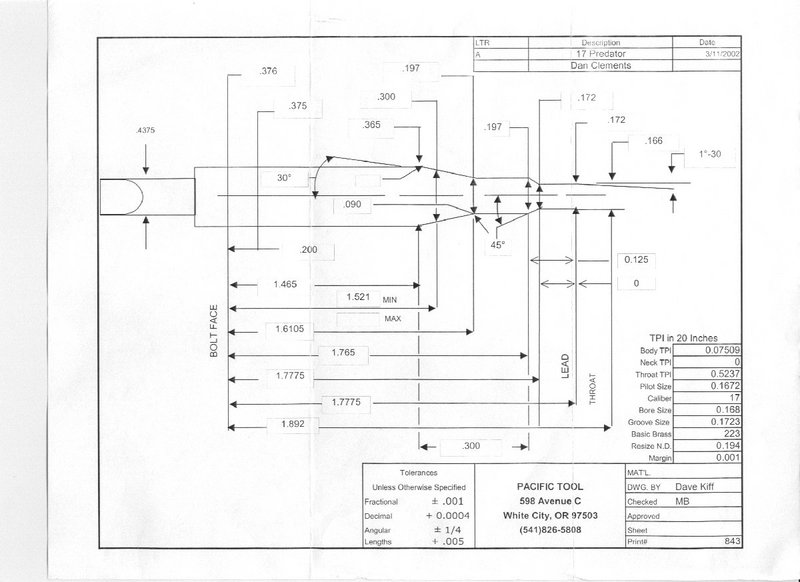

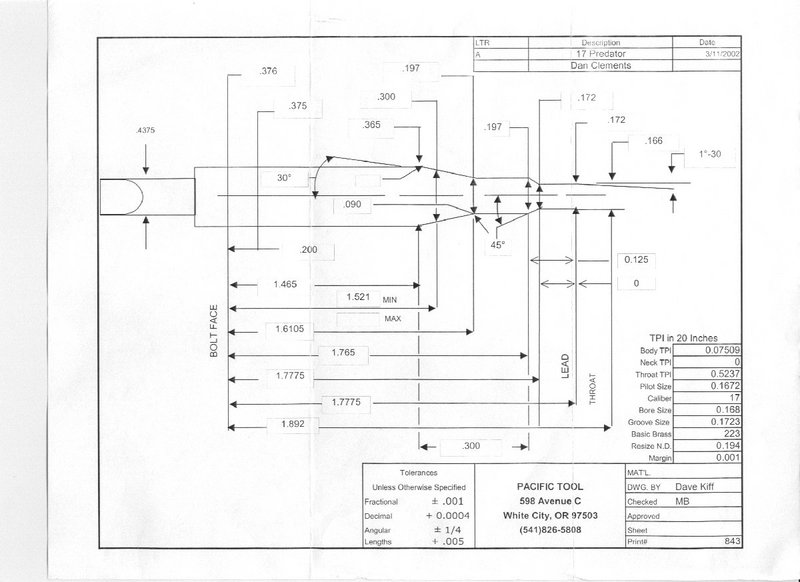

The Cartridge

The .17 Predator is a wildcat designed by Dan Clements, based on the ubiquitous .223 Rem. case. It has significantly more powder capacity than the .17 Rem, nearly equaling the .17 PPC in volume. Dan designed it with enough body taper and mild enough shoulder angle to assure slick feeding from a Rem. 700 action. Top end working loads push 30 grain bullets well over 4000 fps. Using the Kindler 30 gr. Gold’s, with a BC of .270, that translates into some pretty awesome downrange performance in terms of trajectory, wind deflection and terminal energy. For more background on the .17 Predator, see Dan’s original article here.

The Rifle – Action

My first decision on this custom rifle project was choosing an action to build around. After debating the costs, advantages and disadvantages of picking up a Rem. 700 to use as a donor, ordering a new custom action, or simply using one of the rifles already in the safe as a donor, I finally decided to use my old stainless Model Seven .223 as a donor. The rifle had served me exceedingly well, with many thousands of rounds down the pipe and an impressive take of varmints ranging from prairie dogs to coyotes under its belt. But, ever since I had my first .17 Mach IV built, the poor .223 had sat unused. I hate to see any rifle not get used, and the small stainless Model Seven action would both feed the .17P well and make a nice proportionate fit for the cartridge. So, the Model Seven it was!

The Rifle – Trigger

The factory trigger on my Model Seven had been reworked years ago by Neil Jones to a wonderfully crisp 28 oz. It is no coincidence that all of my calling and “field” rifles have that same 28 oz. trigger pull. That is quite a heavy pull by some standards, or quite light by others. For me, it’s “just right” for a rifle of this type. Plus, I find that having all my field use rifles having the same trigger pull helps me to maintain good shooting when switching from one rifle to the other.

The Rifle – Stock

In recent years I’ve been using quite a few rifles all setup in the same stocks, using the same barrel contour, same scopes and same trigger settings. I’ve just found a basic hunting rifle setup that works very well for me, and by having these rifles all setup very close to the same, I’ve found it easy to switch from one rifle to the other and without the need for getting “reacquainted” with things like stock fit, eye relief or trigger pull. The result, for me, has been better shooting in the field with a variety of calibers.

The stocks on these rifles are the Remington Classic factory pattern – both in synthetic copies by McMillan and original factory walnut versions. The factory Rem. Classic stock fits me well, and fits my style of carrying and shooting a hunting rifle in the field very well too. So a call was made to the nice folks at McMillan and another Rem. Classic pattern stock (in desert camo), inletted for the Model Seven action and bottom metal was ordered.

The Rifle – Barrel

The barrels on the rifles previously mentioned are all Lilja #4 contour, 24” long. I have found the #4 to be a great compromise between heavy and light. It is light enough that I have no problem carrying these rifles all day, but still heavy enough to be reasonably stiff for enhanced accuracy, while also adding some stability with the slightly nose heavy balance I prefer for shooting off hand or sitting with crossed sticks. So a Lilja #4 was the automatic choice. Likewise, given that I wanted to use the Kindler 30 gr. Gold bullets, a 1 in 9 twist rate was the obvious choice. My other Lilja .17 caliber barrels are all very accurate and don’t copper foul much, so Lilja was the easy choice.

I did agonize awhile trying to decide on the finished length of the barrel. Dan Clements original .17P had been built with a 26” barrel. I really don’t like a barrel quite that long for a calling rifle – just a personal preference. My other rifles built on similar platforms were all sporting 24” barrels and I wanted to do the same for my .17P. But I was concerned about exactly how much performance I would be giving up with that extra 2” of barrel. The .17P is what I like to call an “intense” cartridge. It has a lot of capacity for the .17 bore, with a fairly low expansion ratio. Or in other words, it’s what many people like to call “over bore”. With any cartridge like this, long barrels allow you to get the most velocity out of all that powder you’re burning. So, there was no question I’d lose some velocity with a shorter barrel. The questions were, just how much velocity would I lose, and could I live with the loss? After much mulling it over and consulting with Dan, I figured I would probably lose somewhere in the neighborhood of 60 to 80 fps by going with a 24” barrel compared to a 26” barrel. I decided I could live with that loss in exchange for what I consider superior handling of the shorter tube. So, a call was made to Dan Lilja, and one of his superb .17 caliber barrels ordered in a #4 contour and with a 1 in 9 twist rate.

The Rifle – Scope

The scope was another easy decision. All the rifles I have setup in the Rem. Classic stocks and using the Lilja #4 barrels are equipped with Leupold 4.5-14×40 scopes, with medium duplex reticles. I could write many pages about how I ended up with this particular scope and reticle on my hunting rifles. But the bottom line, is that for a rifle that will get used on a variety of varmints in a variety of situations, the 4.5-14 magnification is an excellent compromise. Personally, after owning and using them, I see no practical advantage to a 50mm objective on these scopes. Just more bulk, weight and cost. So the 40mm is an easy choice for me. And again, after having used a number of reticle styles, I’ve found the duplex best suits my style for a rifle that sees a good variety of situations. I’ve also found, that for me, I prefer Leupold’s medium duplex over their fine duplex – especially for fast action shooting like called coyotes or jump shooting jack rabbits. If it weren’t for the fact that I also use these scopes for shooting rock chucks and prairie dogs, I’d probably go for the full heavy duplex. I’ve put Leupold’s on these rifles, rather than other makes, mostly due to size and weight. I don’t consider the Leupold’s anywhere near perfect, but do consider them a pretty darn good compromise of optical and mechanical quality vs. size, weight and cost. So, the Leupold 4.5-14×40 with medium duplex that was already on the Model Seven would simply go back into the Burris Signature rings after the new .17 Predator barrel was installed.

The Rifle – Riflesmith

Now that I had all of the components on the way, it was time to call Greg Tannel about my project. This was my first project with Greg. He has built a fantastic reputation among custom rifle fanatics for building superbly accurate rifles. When I called Greg to discuss my project, I immediately felt very comfortable in talking to him. He asked me a lot of questions about many of the finer and more subtle details of my project. Questions that told me he really understood what I wanted to accomplish. Greg not only builds some of the most accurate rifles in the world, but he actually gets out and hunts with them too, and his understanding of application, not just technical details of machining and assembly, really showed. It was really nice talking to a world class rifllesmith who was genuinely interested in my project. Not only interested, but actually excited about it. Greg had built Dan’s .17 Predator, and already had the reamer on hand. We discussed the bullets I would be shooting and how the throating of the chamber should be done to work best with those bullets, plus many other details related to fitting and chambering the barrel. We decided that Greg would give my Model Seven action a complete blueprinting, including his process of reaming the bolt raceway and double bushing the bolt, single point cutting new barrel threads, double pinning a Holland recoil lug in place, plus turning down the firing pin tip and bushing the hole to virtually eliminate the possibility of cratered or pierced primers. Greg’s “works treatment” on a Remington action brings them up to par with the best custom actions. I specified a target style recessed crown at 24” and a bead blast finish for the barrel. I also decided to have Greg pillar bed the barreled action to the stock after he completed all of the metal work. You can read more about Greg’s action blueprinting procedures on his website here.

Loading Dies and Brass Forming

Loading dies and brass forming are always a consideration when planning a wildcat chambering. For the .17 Predator, I was able to use my existing .17 Mach IV forming dies to neck down the .223 brass by simply backing the dies out of the press an appropriate amount. Since the shoulder of the .17P is slightly longer than that of the parent .223 case, the “false shoulder” created in the neck when reducing the neck diameter is what gets used to hold headspace during fireforming. So, initial case forming was a very simple and straightforward operation. For regular neck sizing after fireforming, I’ve simply continued using a Redding Type S .17 Mach IV die adjusted to the correct height in the press. For bullet seating, I sent Greg Tannel a .17 Remington Redding Competition seating die and had him run the .17 Predator chambering reamer into the floating sleeve. This combination of dies loads wonderfully concentric ammo, with absolutely no headaches or special hoops to jump through. Dan Clements had a couple of .17 Predator full length sizing dies custom made for us, but so far, even with some cases loaded 10 times now, I have not needed to use the FL die yet. It appears to me that I’ll be wearing out primer pockets and discarding cases without ever needing to FL size them. You can read more detail about choosing dies and forming cases for the .17 Predator in Dan’s original article – here.

Load Work

When I got the completed rifle back from Greg, I found myself with very little time to do load development. Luckily, I had all of Dan’s data to start with. Sometimes on a rifle project, things just seem to all come together and work well right out of the gate, almost with no effort, like it was just meant to be. I love it when that happens. My .17 Predator turned out that way.

My goal for the first range session was to work up a decent fireforming load. To start with, I simply loaded up a few rounds with the fireforming load Dan had reported getting good results with – 30 Gold’s seated into the lands and 24.5 gr. N540. After using the first three shots to get zeroed, the first pair of three shot groups were both under 1/3 MOA, and the cases were nicely formed with crisp blown out shoulders. The chronograph showed 3800 fps for these loads while fireforming. Good enough for me! With less than 10 shots put on paper, I was done with load work or target shooting for the time being. I went home and loaded up the remainder of 100 pieces of brass with that fireforming load, and looked forward to fireforming the rest of my cases while stopping beating hearts!

After getting some more cases fireformed (on rock chucks!), I then tried the two full house loads for the 30 gr. Gold that Dan had reported were working well for him. One with N550 and one with Big Game. His Big Game load was a bit hot for my rifle, so I backed it off. What I ended up with, are two loads that both push the 30 grain Gold’s to 4050 fps or so, with superb accuracy. The N550 load is 27.1 grains and produces 4040 fps, the Big Game load is 27.5 grains and produces 4060 fps. All loads are using the Kindler 30 gr. Gold bullet, seated to make firm contact with the lands. The load using Big Game showed slightly better accuracy, along with slightly better velocity. It’s also a fine grained ball powder that meters well (meaning I don’t have to weigh charges), so that is the one I settled on as my working load. All total, I’ve shot only about a dozen groups with the rifle, and most of those only 3 shot groups. But only one group out of all of them has been over .5”, several have been under .25”. Considering I’m getting the velocity I wanted, and the accuracy I wanted, I simply see no need to continue load testing. With less than 60 total shots on paper, I was done with load work and ready to go hunting. Now, a couple years later, I can report that I have one set of IMI cases that have been loaded 8 times now with the Big Game load and the primer pockets are still tight and the brass appears to be holding up well. Most likely, the only paper this rifle will ever shoot for the rest of it’s life will be to check zero!

In the Field

Now this is the GOOD part! Back when I read Dan’s first Small Caliber News article about the .17 Predator, I was just finishing up the design stage and starting to build a new rock chuck rifle. My goals for that rifle were a rifle to deliver as much energy as possible in a package I could reasonably carry around and still have some chance of seeing my own shot impacts in the scope. That turned into a 14 pound 6MM Ackley Improved with a Vais brake (the project didn’t really work out, but that’s another story…). Anyway, as I mentioned at the beginning of this article, when I first read about the .17 Predator, one of the first things that came to my mind in looking at the spec’s for the .17P, was that it would make one Hell-on-wheels walking chuck rifle! It has flatter trajectory and less wind drift than all but the very hottest .224’s shooting 55 gr. bullets (it takes a very hot Swift load, or a .223 WSSM to match the .17P for trajectory or wind deflection). Using the 30 gr. Gold bullets at over 4000 fps, the .17P delivers 400 ft/lbs at 500 yards. And it gives you all this in a package that allows easily spotting your own shot impacts through the scope with even a fairly lightweight and easy to carry rifle. Well, after my first day hunting with my .17 Predator, I found that it IS, for a fact, a big time Hell-on-wheels walk-n-pop chuck rifle!

As it turned out, a snowdrift across the road (in late July) prevented me from driving all the way in to my high country chuck hunting spot for my first day hunting with the .17 Predator. So I ended up taking a good 4 mile hike above timberline, at about 11,000 feet elevation, carrying the .17 Predator. I killed 26 rock chucks with 27 shots, and every one of those 26 chucks was a clean, instant one shot kill, and I saw every single hit cleanly through the scope. This was using the fireforming load too, by the way. Truly a memorable day of hunting and absolutely stunning performance from the new rifle. I was one happy ‘chuck hunter!

Well satisfied with every aspect of the .17P after my chuck hunt, I was super anxious to try it on prime winter coyotes. Finally, October arrived and I couldn’t stand to wait any longer. Even though I had rock chucks on the brain at the time I started to have my .17P built, the real purpose I had in mind for it was as an “every stand” coyote calling rifle. Just as the first day out chuck hunting had turned into a truly memorable experience, so too did my first day of coyote calling with the new rig turn into something special. When the day finally arrived, my partner Tim and I went out to one of our favorite coyote hunting spots to try out both my .17P and a new FX3 caller from Foxpro. It turned out to be one of those rare days that the coyotes just seemed to be finding our calling irresistible, as we had coyotes come in on most of the stands we made. I ended up getting shots at 5 coyotes myself, killing 4 (missed the other one clean). And once again, I could not have been more pleased with the performance of the .17 Predator. As it turned out, I got to see quite a variety of shot angles and hits for one day. You can read a blow-by-blow damage assessment of the first 8 coyotes killed with my .17P here. One thing that became very clear by the end of the day, is that those 30 grain bullets, moving out at over 4000 fps, hit one heck of a lot harder than the 25’s out of my .17 Mach IV that I’m used to! With proper bullet placement, this should be a very fur friendly setup. With less than ideal bullet placement, there is going to be some fur damage, but, there is enough energy and bullet integrity there that I feel the chances of actually losing a poorly hit coyote are greatly reduced as compared to my Mach IV. Simply put, the .17P is delivering a lot more energy, with significantly greater penetration. But I still get that neat experience of seeing the impact clearly though the scope, and that awesome, all out of proportion to bullet size meat report that the .17’s give on coyotes.

I’ve put together a video clip of scenes from our coyote hunting video, “Varmint Safari 4, Tricking the Trickster”. In this clip you can see the .17 Predator in action on called coyotes. To see the video clip, click here.

Conclusion

Now, after just over one hundred coyotes killed with my .17 Predator, plus several high country rock chuck hunting trips, a couple of prairie dog shooting sessions as well as a couple of days shooting jack rabbits with it, I’m even more pleased with this rifle than I was to start with. Simply put, this project has turned into my favorite all around varmint/predator hunting rifle to date! I like everything about it, the weight, the balance, the feel, the performance, case life, the accuracy, even the looks. If I had it to do over, I don’t think I’d change a thing. I can’t think of too many rifles I’ve had built over the years that I can say that about!

– Dave Affleck

Update 2017

I can’t believe it has already been fourteen years since I decided to have a .17 Predator built. But, here I am, fourteen years later and still in love with the cartridge and the rifle! I’ve played with quite a few others during all these years and love some of them too, but the .17 Predator is still my “main squeeze” and the one I love the most. Simply put, if I could only have one rifle to hunt coyote with the rest of my life, I’d choose this one without a second thought.

Dave ,

How’s it going? Glad to see you still share my enthusiasm for the .17 Predator!! It is one fantastic Coyote Chambering. I took 2 sleepers at longer range last season, one at 350 and one at 425. Both were dead in their beds. Shooting the 30 Nagel at around 4k and it seems to do the trick. I wish the Golds were available but evidently the young man in Texas has lost enthusiasm for bullet making.

Thanks for the guidance early on and work you and Dave did on load development.

Accurately,

Timothy

Still going “pretty good”! How about you Timothy? Well I hope!

It does appear the Texas Golds were short lived. A shame. But, he only had just so many of the long J4s jackets needed, too, so it was only going to be a short run at best.

Hi Dave, I have just re-read your 17 Predator article with renewed interest. After several years of very enjoyable shooting, my 17 Mach IV is about to give up the ghost. Even using the new CFE powders, metal fouling is nearing the intolerable stage. This puts me in the position of deciding which cartridge to chamber a new barrel for. The 17 Predator looks enticing. I have experienced a few runoffs using the 17 Mach IV on coyotes even with solid hits, but mine is a 10 twist and I never tried to shoot 30 grainers with it.

As I consider a few larger capacity 17 caliber cartridges as replacements for my ailing Mach IV, a relevant question pops up. Are there quality 30 grain 17 caliber bullets still available? Is Kindler, Nagel, or anyone else making them now? The availability of 30 grain bullets figures heavily in my decision on this project.

As always, I enjoy your articles and very much appreciate you sharing your experience & knowledge.

Long time Ted! Great to hear from you!

You have hit upon the crux of the matter – getting good 30 gr. bullets. I would not start a project intended for them until after acquiring the bullets. Right now, the best I know of, which are usually available, but which aren’t always available in quantity, are Chan Nagels. I’d start with a call to him.

Dave, very sad to see that you’ve joined ranks with the red”fraud” on Predatormasters. That is soooo beneath you…the kickbacks and opportunity to ban people must of been too tempting for you.

again, sad….

Hahahahaha! You are a funny guy! Redfrog isn’t even alive anymore. But, never mind that, please tell me about these kickbacks, I hadn’t heard of them before. Who do they come from? When I joined the BoD less than two months ago, there wasn’t a single paying sponsor at predatormasters. So, I’m curious, who is paying these kickbacks, what are they getting in return? I’d love to know. And apparently, you do know, so please, tell me all about it. You seem to know way more about how things work than I do. Heck, according to you, I might even be dead and don’t know it, since I’ve joined ranks with Redfrog?