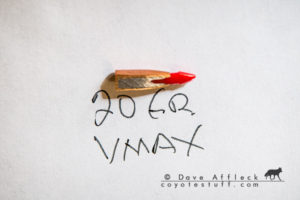

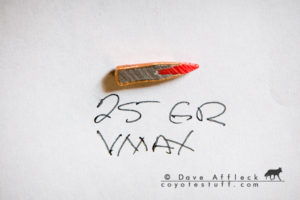

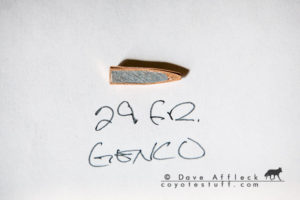

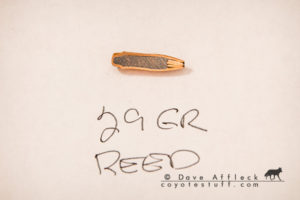

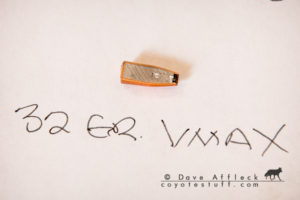

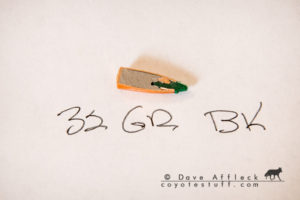

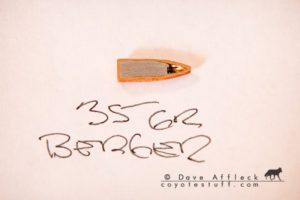

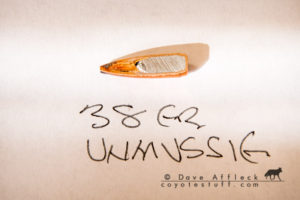

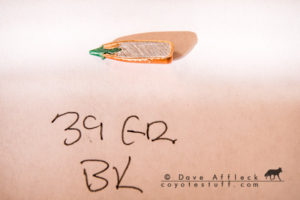

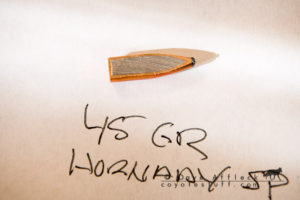

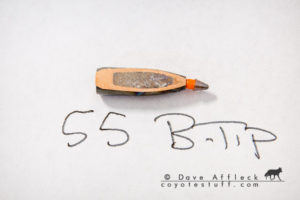

Sectioning bullets to see how thick a jacket is, or how deep a hollow point might be, is something I think most long time hand loaders have tinkered with at least a little bit. I’ve done a couple, here and there, over the years.

I saw a post on one of the forums last year, few different guys posting pictures of a lot of different sectioned bullets. Being in separate posts and running across a couple pages made it not super easy to compare some of them. So I got the idea to section a bunch of bullets at once for a picture gallery. Finally getting around to it!

I didn’t get a sample of everything on the shelf. I just went for the varmint bullets towards the front of the shelf, .17, .20, .22 and 6mm calibers. I have many more I didn’t do, especially the .22’s. If there’s a varmint bullet I didn’t do that you would like to see, leave a comment. I’ve probably got it on the shelf and I’ll get them added (eventually, ha-ha!).

This was pretty quick and dirty. I put each bullet in a pair of vise grips, then used a little Harbor Freight belt sander to flatten them down.

The sectioning is very far from precise – these aren’t center-lined or even very consistently sectioned. The vise grips pinched and slightly misshaped some of the bullets, especially the .17’s. The tips fared poorly, both plastic and lead.

But, for all that, you can get a pretty good look at the construction and jacket thickness of them. The results are good enough for my purposes. Hopefully it helps someone else too.

It’s interesting to compare observed performance with visible differences in construction like jacket thickness. I know looking at a Vmax and a Ballistic Tip side by side, what I see, matches what I’d expect based on terminal performance I’ve experienced.

Sectioned Bullets

Nice job halving the bullets. The Nagle may have the thickest copper jacket.

The Nagel is a really good coyote bullet too. One of the best.